SETTING THE BENCHMARK

SETTING THE BENCHMARK

Make sure the boiler you choose ticks all the boxes…

It’s difficult to appreciate the difference between one boiler and the next if you don’t deal with oil boilers on a daily basis. Here are some of the important features to consider when selecting the best oil-fired boiler.

Five Year No Quibble Warranty

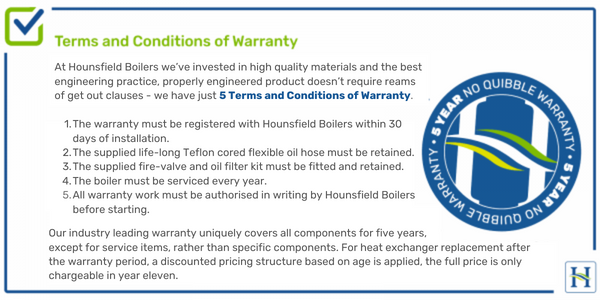

Warranty is an important consideration when choosing a new boiler. Some manufacturers offer attention grabbing long warranties but with pages of small print. These warranties can be misleading. Investigate the small print in Terms & Conditions, and the cost of complying with them can result hefty bills for replacing components at specified intervals. You may end up effectively paying for the cost of a new boiler over the warranty period.

At Hounsfield Boilers we’ve invested in high quality materials and the best engineering practice, properly engineered product doesn’t require reams of get out clauses – we have just the following terms and conditions of warranty.

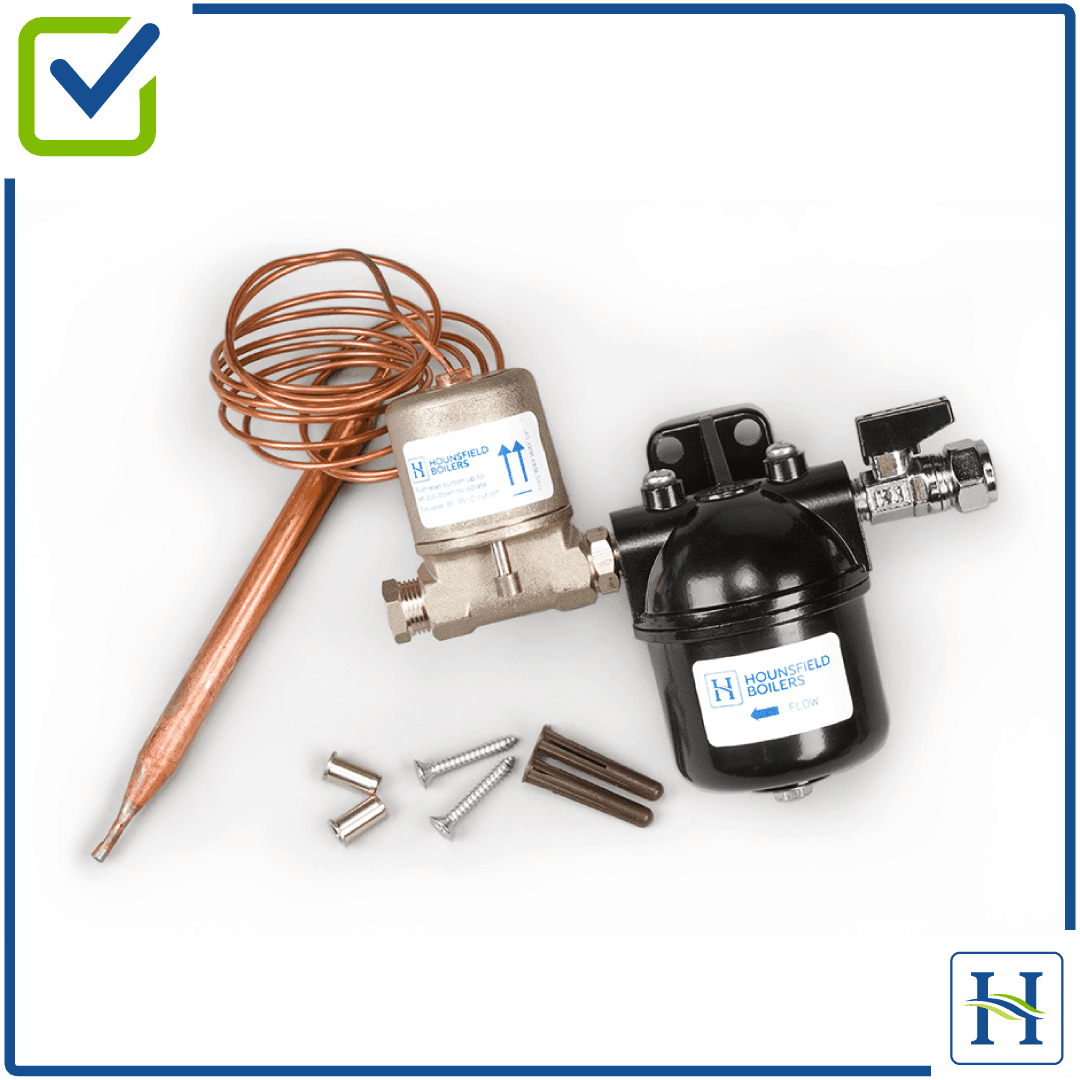

- The warranty must be registered with Hounsfield Boilers within 30 days of installation.

- The supplied life-long Teflon cored flexible oil hose must be retained.

- The supplied fire-valve and oil filter kit must be fitted and retained.

- The boiler must be serviced every year.

- All warranty work must be authorised in writing by Hounsfield Boilers before starting.

Our industry-leading warranty uniquely covers all components for five years, except for service items, rather than specific components.

For heat exchanger replacement after the warranty period, a discounted pricing structure based on age is applied, the full price is only chargeable in year eleven.

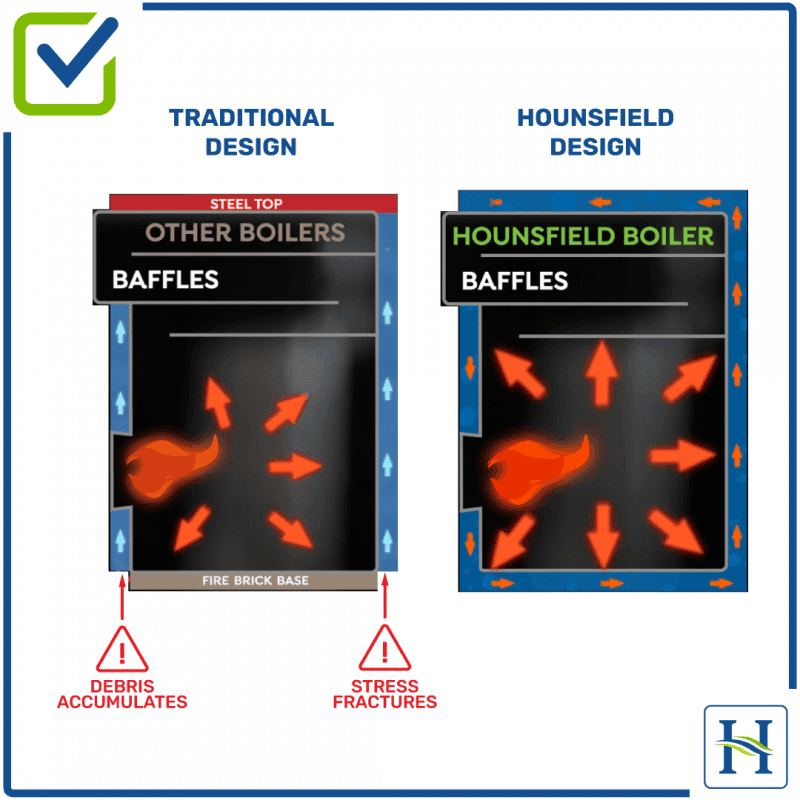

Modern Efficient Heat Exchanger Design

Traditionally designed domestic oil boilers have a fire brick in the base with a steel plate or covers on the top.

Our heat exchanger design, with water surrounding the combustion box, requires a more complex specialised manufacturing process but produces a more efficient unit by maximising the heat transfer surface area.

Stress fractures caused by “hot spots” are avoided. Improved water circulation reduces the potential for corrosion caused by debris accumulation in the bottom of the heat exchanger.

High quality welding is a key feature of a Hounsfield Boiler. State-of-the-art Fronius synergic pulsed arc welding equipment ensures consistent weld quality. Another reason to choose a Hounsfield boiler.

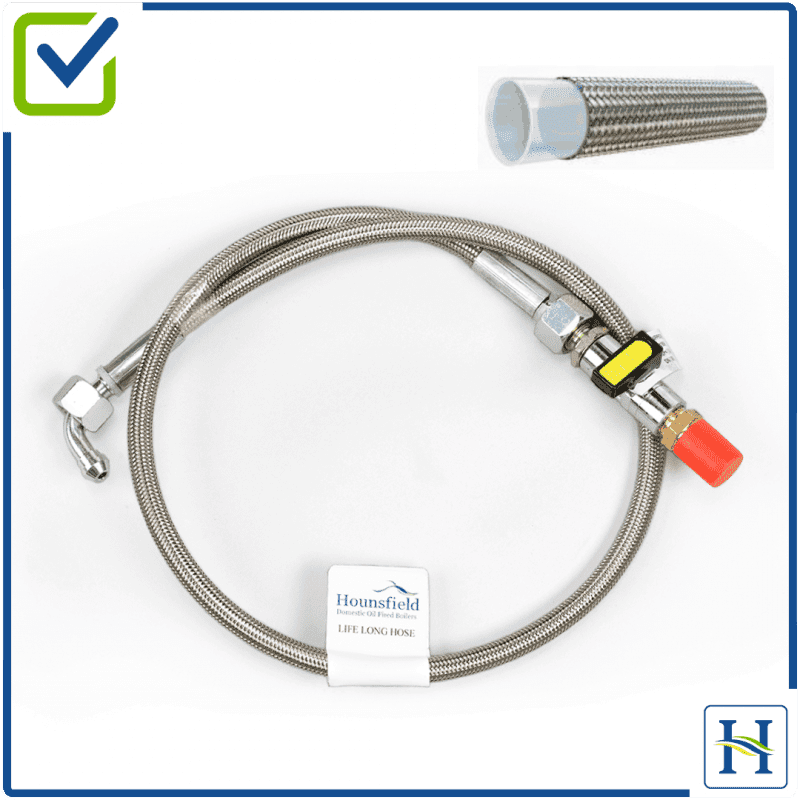

Life-Long Flexible Oil Line

It’s common for manufacturers to require the flexible oil lines supplied with a new boiler to be replaced at the first annual service. Some replacement hoses are referred to as ‘long-life’ but all are made of rubber or thermoplastic, which will degrade and require regular replacement.

Oil leaks caused by failed out-of-date hoses can result in expensive insurance claims for you or your engineer. We think that’s unacceptable and that hoses of “merchantable quality” should be supplied in the first instance.

For peace of mind for you and your service engineer, aircraft grade oil line hoses are ‘life-long’ rather than just ‘long-life’. Teflon™ cored with stainless steel braiding, our oil lines will not degrade or require regular replacement. Setting the benchmark for boilers. Another reason to choose a Hounsfield boiler.

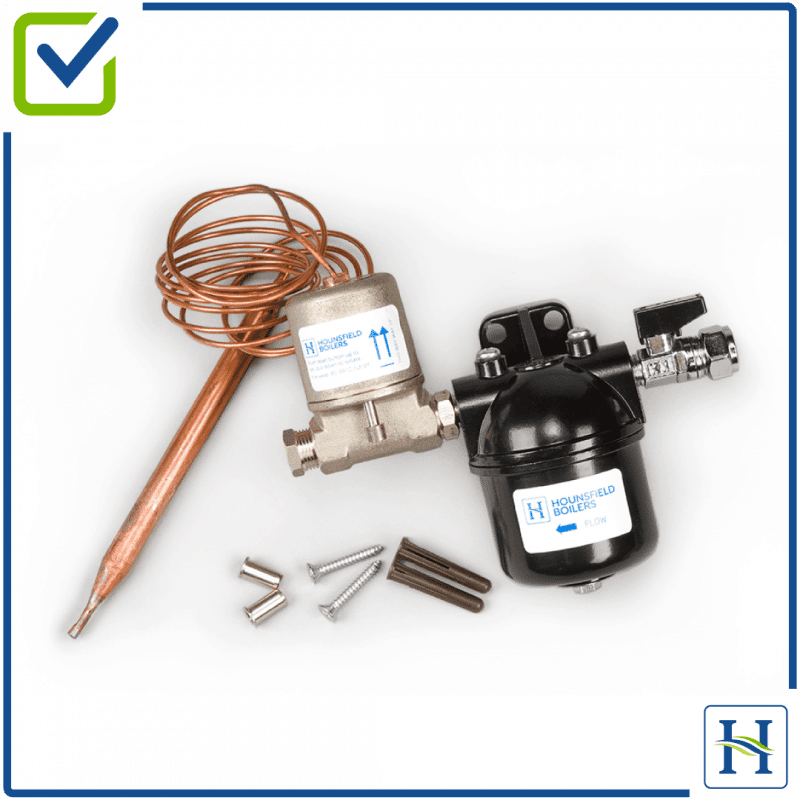

Everything is in the box saving hassle

Yes, our boilers really do come with everything needed to install them, including a fire valve and oil filter assembly. Historically, paper element oil filters were supplied as standard with most oil-fired boilers. Unfortunately, this is seldom the case these days.

A paper element filter is essential. Gauze filters commonly used do not provide adequate filtration and often lead to expensive premature boiler failure.

In supplying an oil filter kit, we’re controlling the quality of filter installed. This will save you money in the long term and save your installation engineer the hassle of sourcing these components. Setting the benchmark for boilers. Just one reason to choose a Hounsfield boiler.

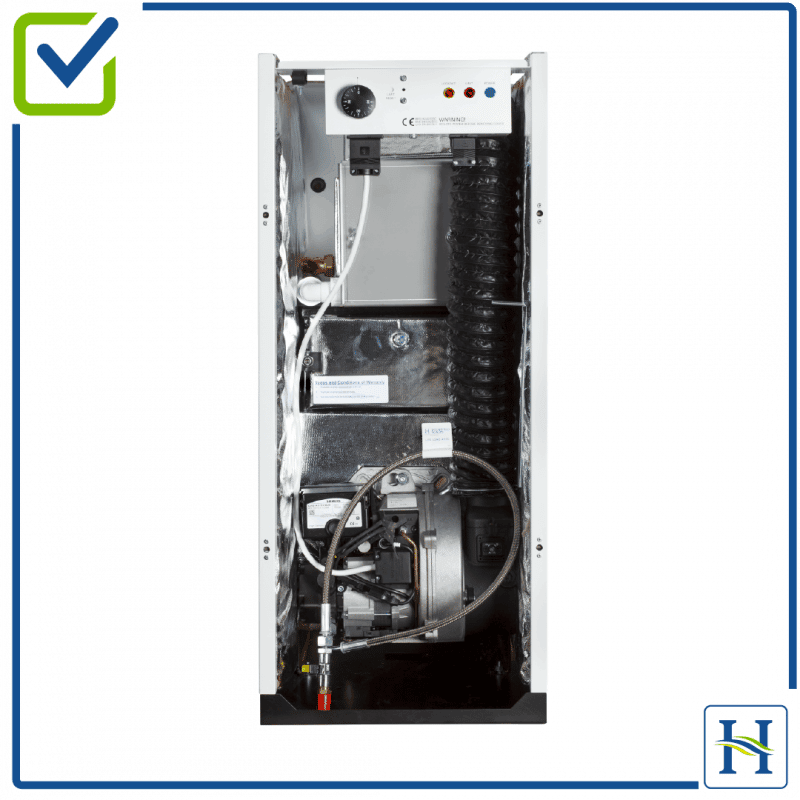

Fully Insulated Casing for Whisper Quiet Operation

It’s common industry practice to insulate boiler water jackets with a low-grade insulation, boiler casings often left un-insulated. We insulate the water jacket and also the boiler casing, as you’ll see in the video, with high grade 45kg Rockwool. This improves standby heat losses and also makes our boilers extremely quiet.

Make sure your boiler ticks all the boxes…

5 Year No Quibble Warranty

Modern efficient Heat Exchanger design

Life-long Flexible Oil Line

Paper element Oil Filter and Fire Valve kits included

Fully Insulated Casing for whisper quiet operation

Bespoke Elco Burner is HVO ready

Ultra safe controls and Visible Neons

Plug and Play Electrics

Versatile Flue Options – One system fits all

Single Oil Pipe Supply – no need for Tigerloop

Elco Burner made to our specifications

Burner by Ariston Thermo (HVO ready)

We are delighted to introduce a new burner to our oil-fired boilers.

Installers know the components we use are second to none and thanks to our constant desire to be the very best oil boilers on the market, we’ve been working hard with Elco, part of the Ariston Thermo Group, to develop a burner of exceptional quality, ease of service and is at the forefront of combustion technology.

The team at Elco is managed by Guiliano Corticini, formerly with Riello, he has many years’ experience in the design of domestic oil burners, and an aligned passion for attention to detail.

Our Elco burner uses the same industry standard components we specified on the Bentone BF1 burner which means lower life-time costs for spare parts. These are around 30% lower than bespoke Riello burner components.

The Elco burner is able to run on HVO (Hydrotreated Vegetable Oil) fuel. HVO is a green bio-fuel that reduces CO2 emissions by 91% when replacing kerosene.

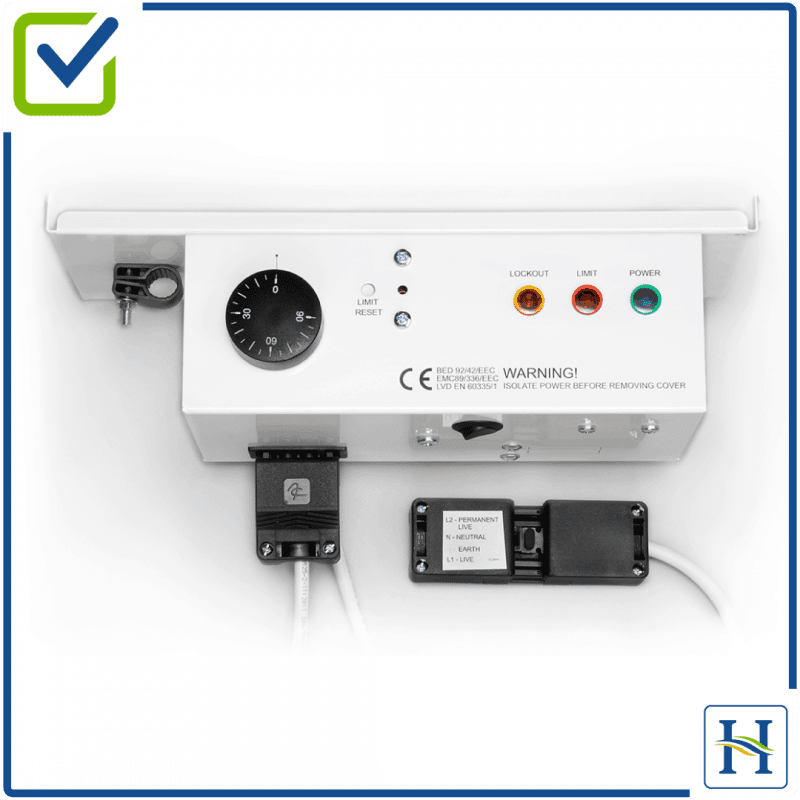

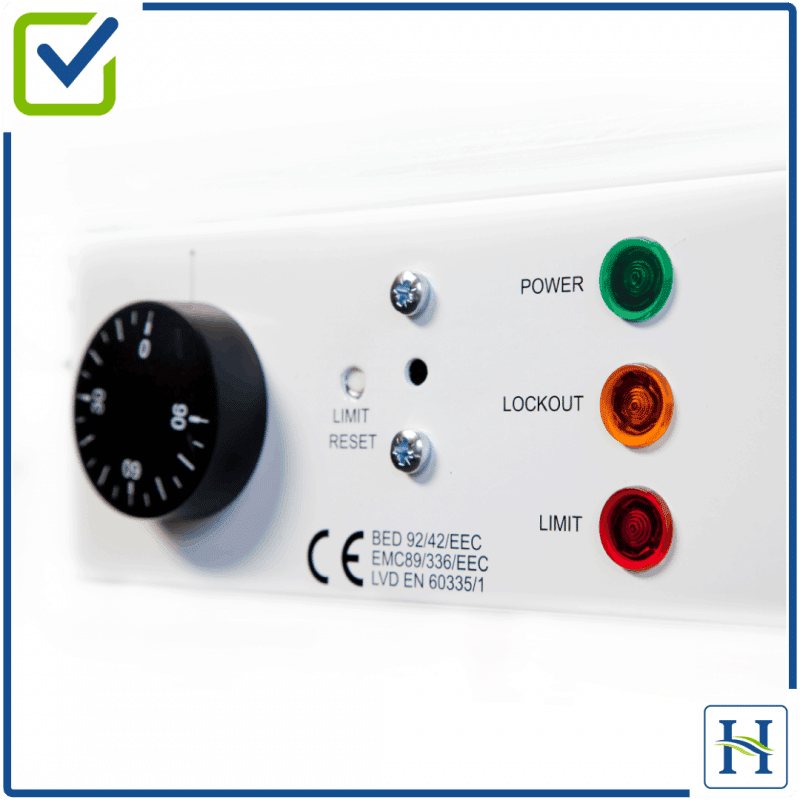

Boiler Controls, Child Proof, User Friendly, Ultra Safe

Every Hounsfield Boiler has neon indicators that are clearly visible through the boiler casing to communicate boiler status for mains power, burner lockout and high temperature lockout.

An essential diagnostic aid for homeowners and engineers, these are by no means standard on oil fired boilers. They can save the cost of calling out an engineer simply to press a reset button.

We fit over–heat limit thermostats set at 90°C, the industry norm is 110°C. We believe this temperature is too high and potentially unsafe. Incidents of boiling water pouring through ceilings have occurred as a result of this excessive high temperature. Our lower temperature setting also provides additional protection to the boiler and its components.

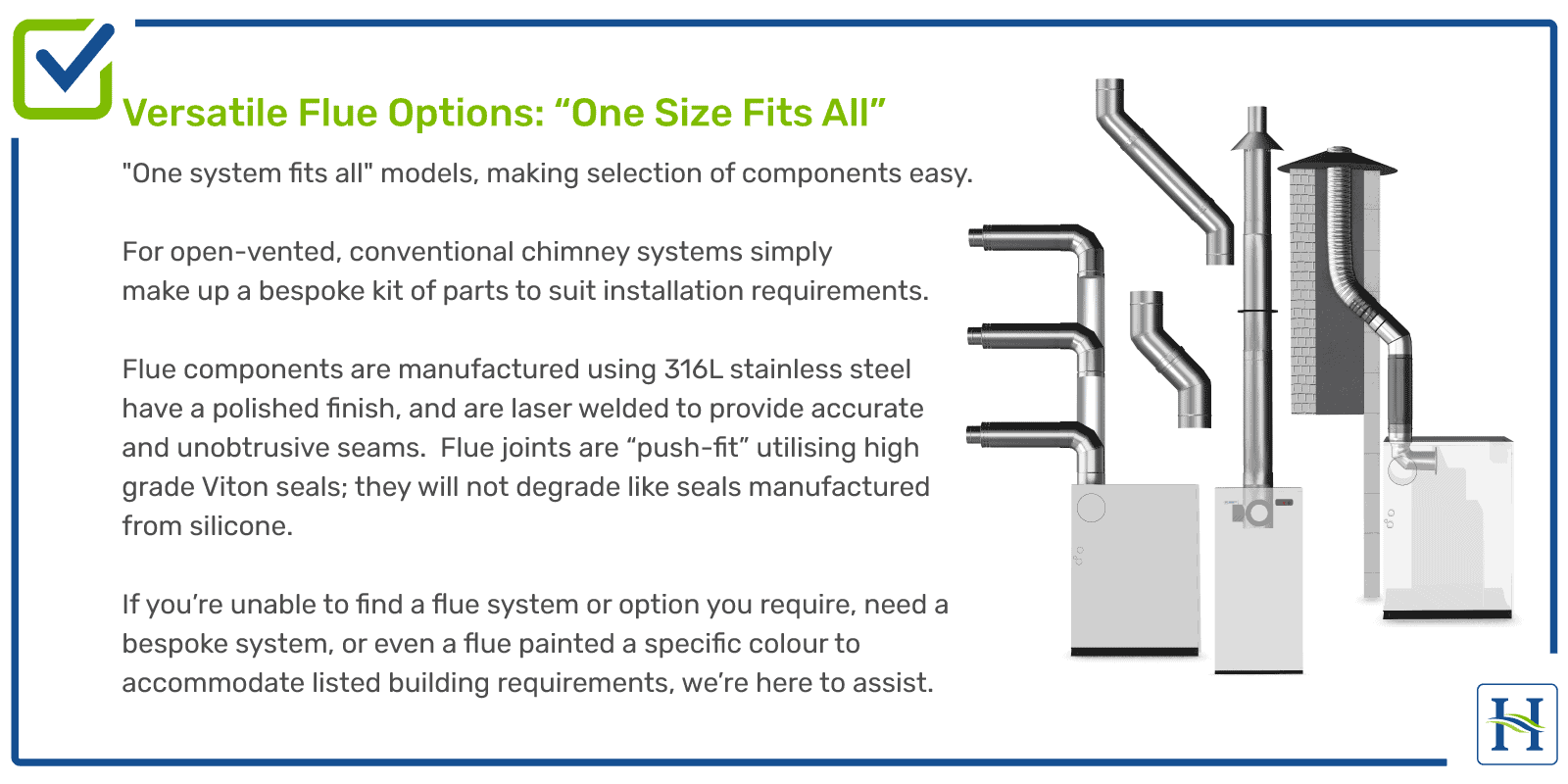

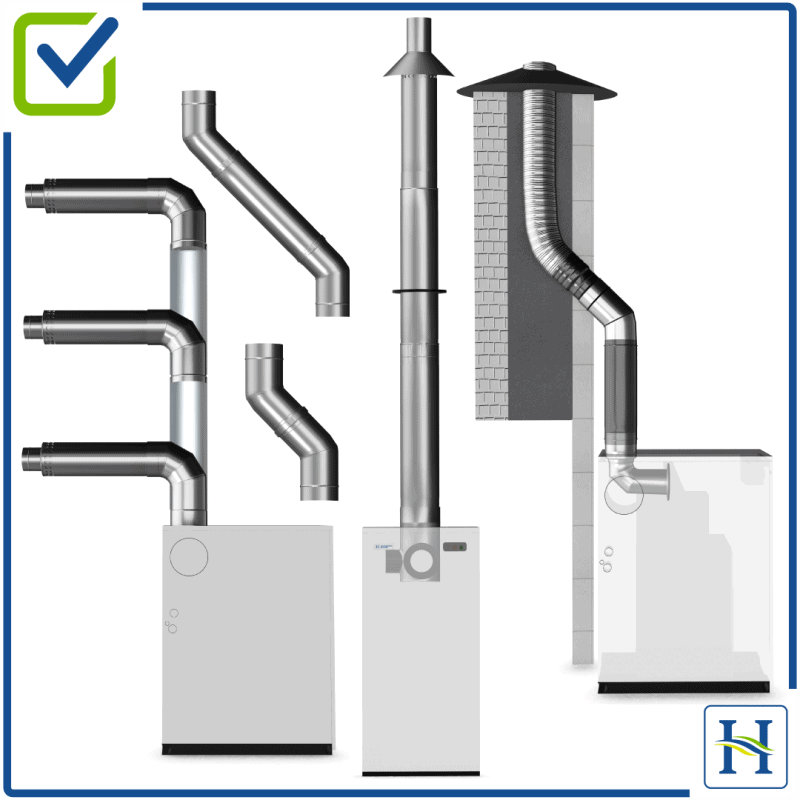

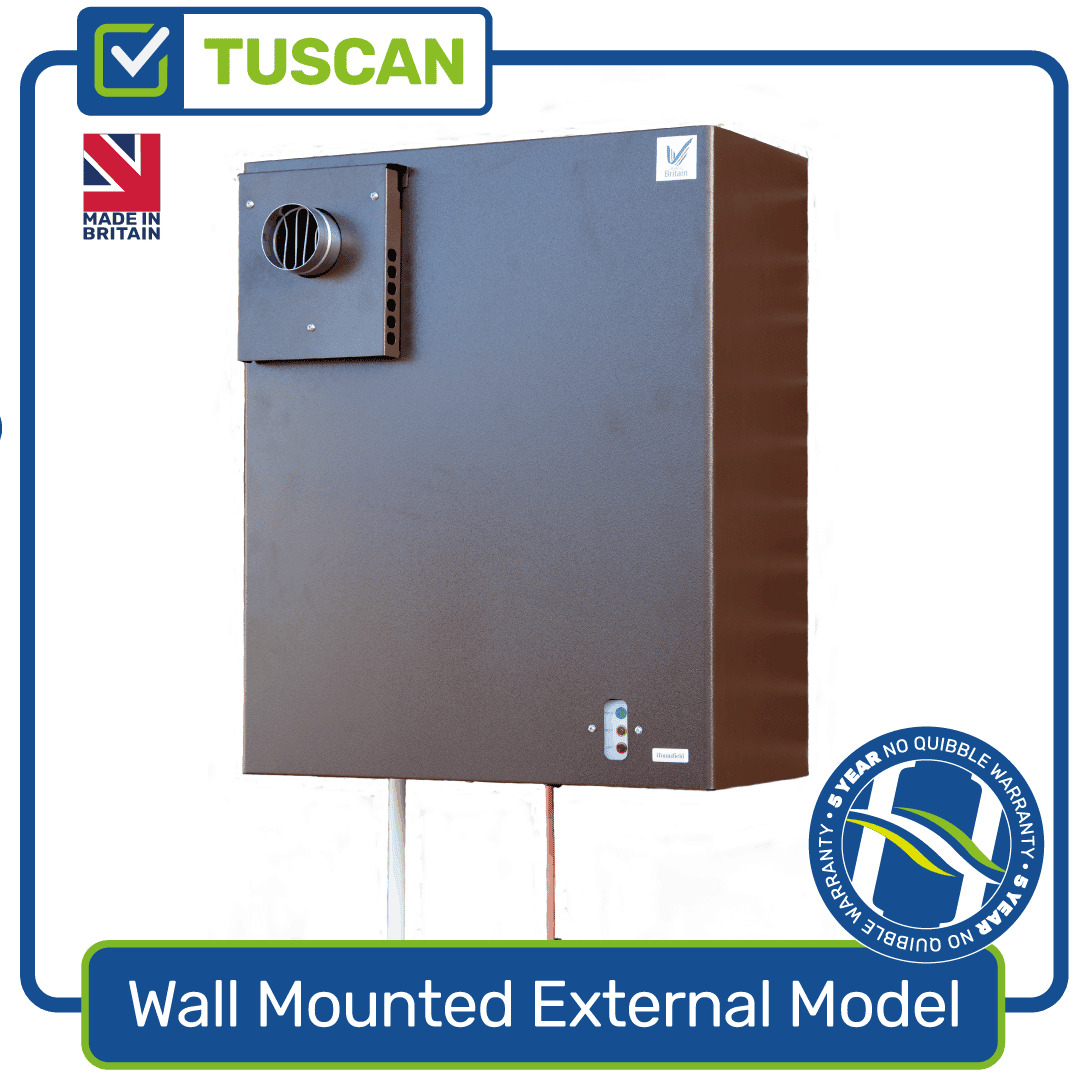

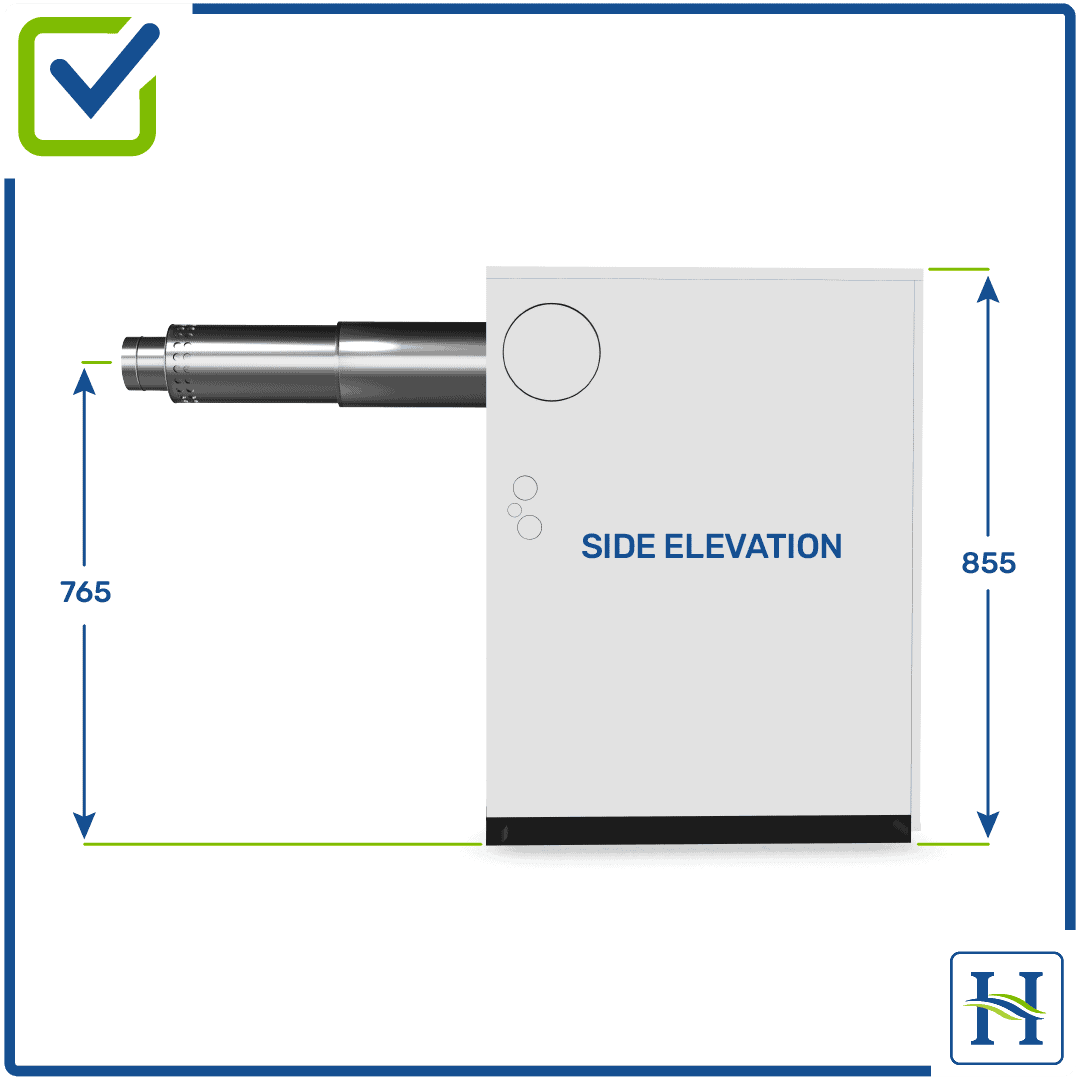

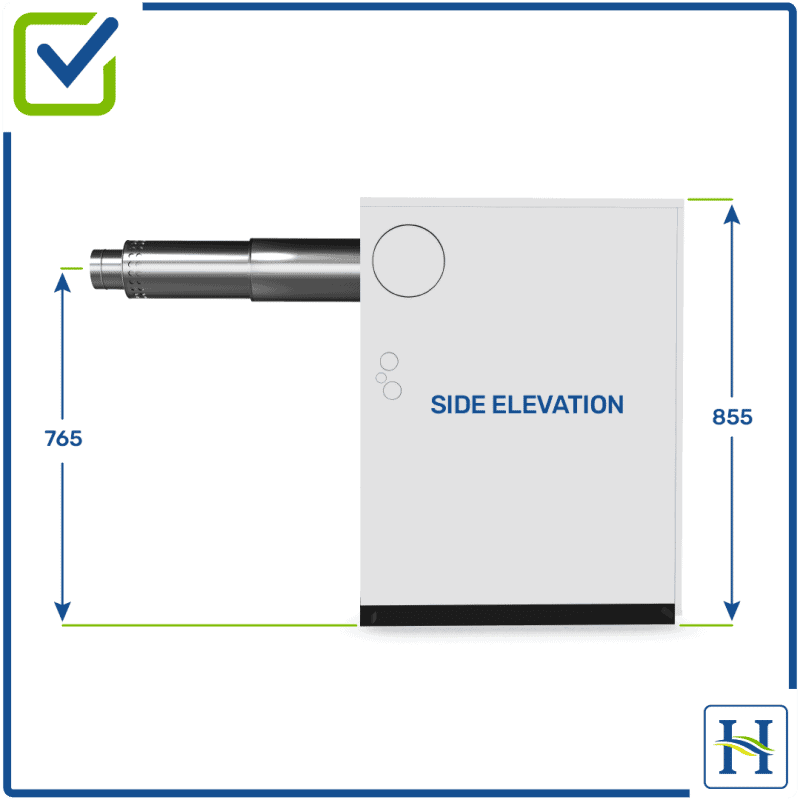

Versatile Flue Options: “One Size Fits All”

“One system fits all” models, making selection of components easy.

For open-vented, conventional chimney systems simply make up a bespoke kit of parts to suit installation requirements. (See Conventional Flue options)

Flue components are manufactured using 316L stainless steel have a polished finish, and are laser welded to provide accurate and unobtrusive seams. Flue joints are “push-fit” utilising high grade Viton seals; they will not degrade like seals manufactured from silicone.

If you’re unable to find a flue system or option you require, need a bespoke system, or even a flue painted a specific colour to accommodate listed building requirements, we’re here to assist.

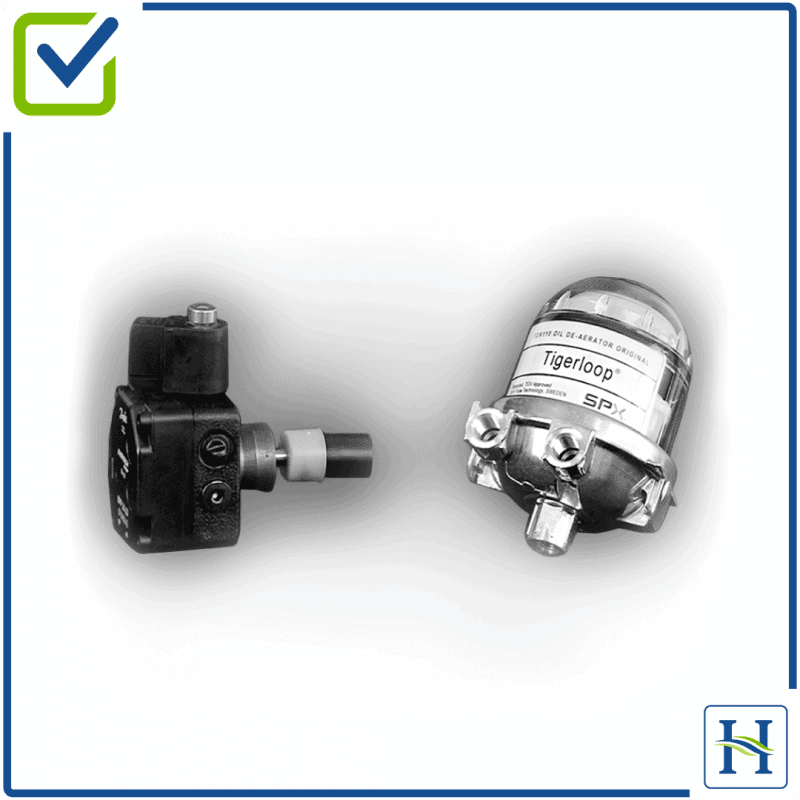

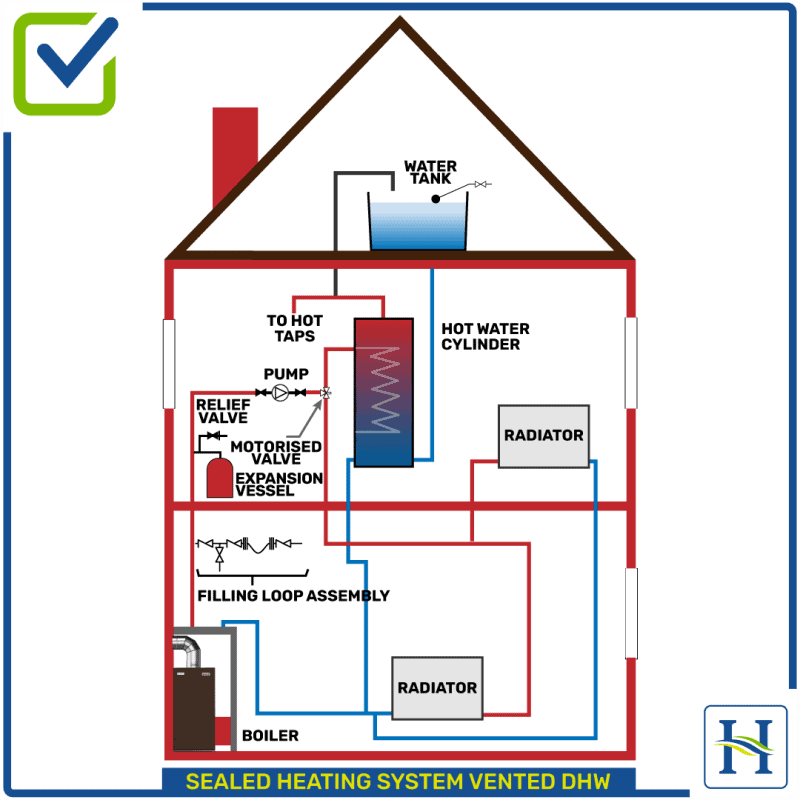

Single Oil Pipe Supply System – no need for Tigerloop

We only use materials and components that will provide many years of trouble-free servicing thereby keeping whole-life running costs to a minimum.

Deaerators such as Tigerloops are often used where oil level is below the burner, when installing wall mounted boilers for example. These are not required with Hounsfield oil fired boilers saving installers time and homeowners associated long-term maintenance costs.

Deaerators resolve a technical issue with Riello burner fuel pumps. The fuel pump we specify has a design suction capacity of minus (-) 0.6 to minus (-) 0.8 bar. Minus 0.33bar is equal to a 4-metre head (height from the minimum tank oil level to the burner).

Hounsfield Boilers DO NOT require deaerators/Tigerloops

Made in Britain

We’ve been granted use of the “Made in Britain” logo.

Tuscan Boilers are manufactured at our premises near Stowmarket in Suffolk.

Award Finalists

We’re proud that our boilers have won prestigious industry awards in recognition for their high-quality and innovative design.

We won a ‘Highly Commended’ for the H&V News Awards for ‘Domestic Product of the Year 2020”.

SETTING THE BENCHMARK

SETTING THE BENCHMARK