If you’re replacing an old boiler it’s a good opportunity to review and upgrade your existing heating system, here’s an overview of the pros and cons of typical heating systems.

Typical Heating Systems Explained

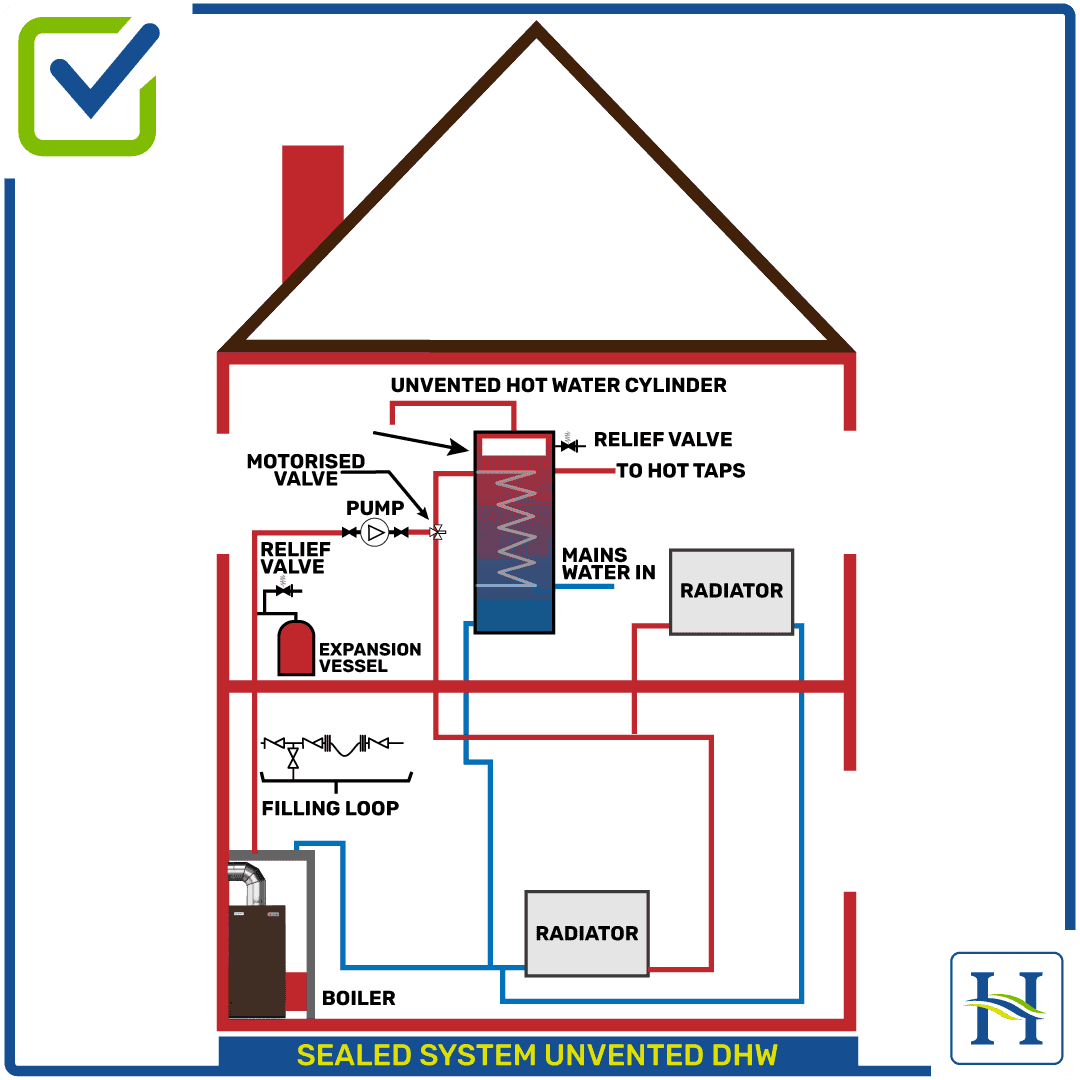

SEALED SYSTEM, UNVENTED HOT WATER DHW

A sealed heating system with an unvented domestic hot water tank is the optimum system for a modern installation.

PROS:

- A pressurised hot water cylinder such as the Heatrae Sadia Megaflow will provide up to 72 litres per minute of hot water at mains pressure.

- This is the best engineered solution with low life-time maintenance costs.

- There are no tanks in the loft to protect from frost, cylinders can be located at ground floor level, for example alongside the boiler.

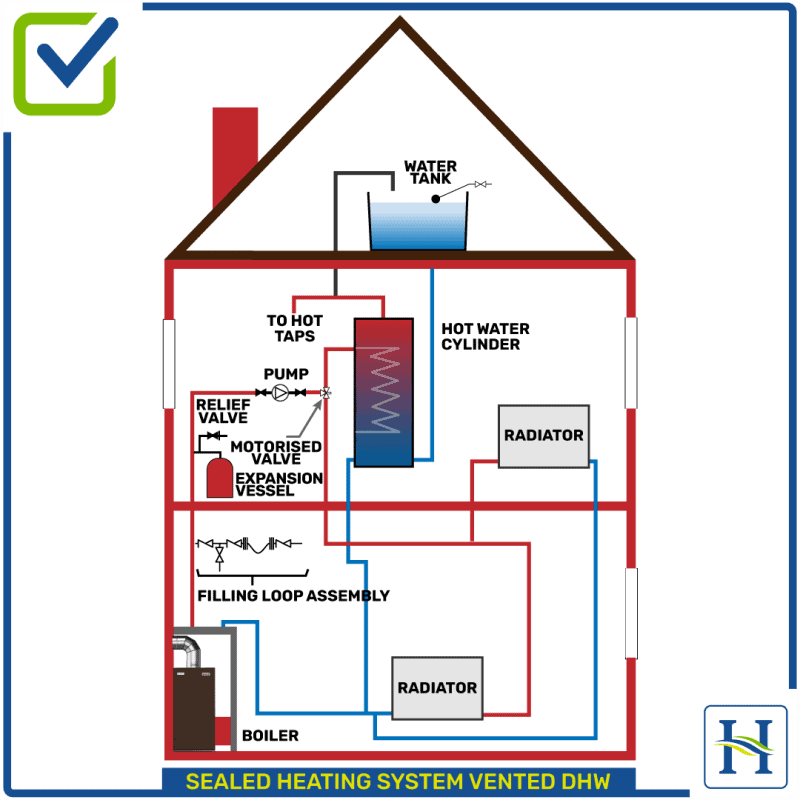

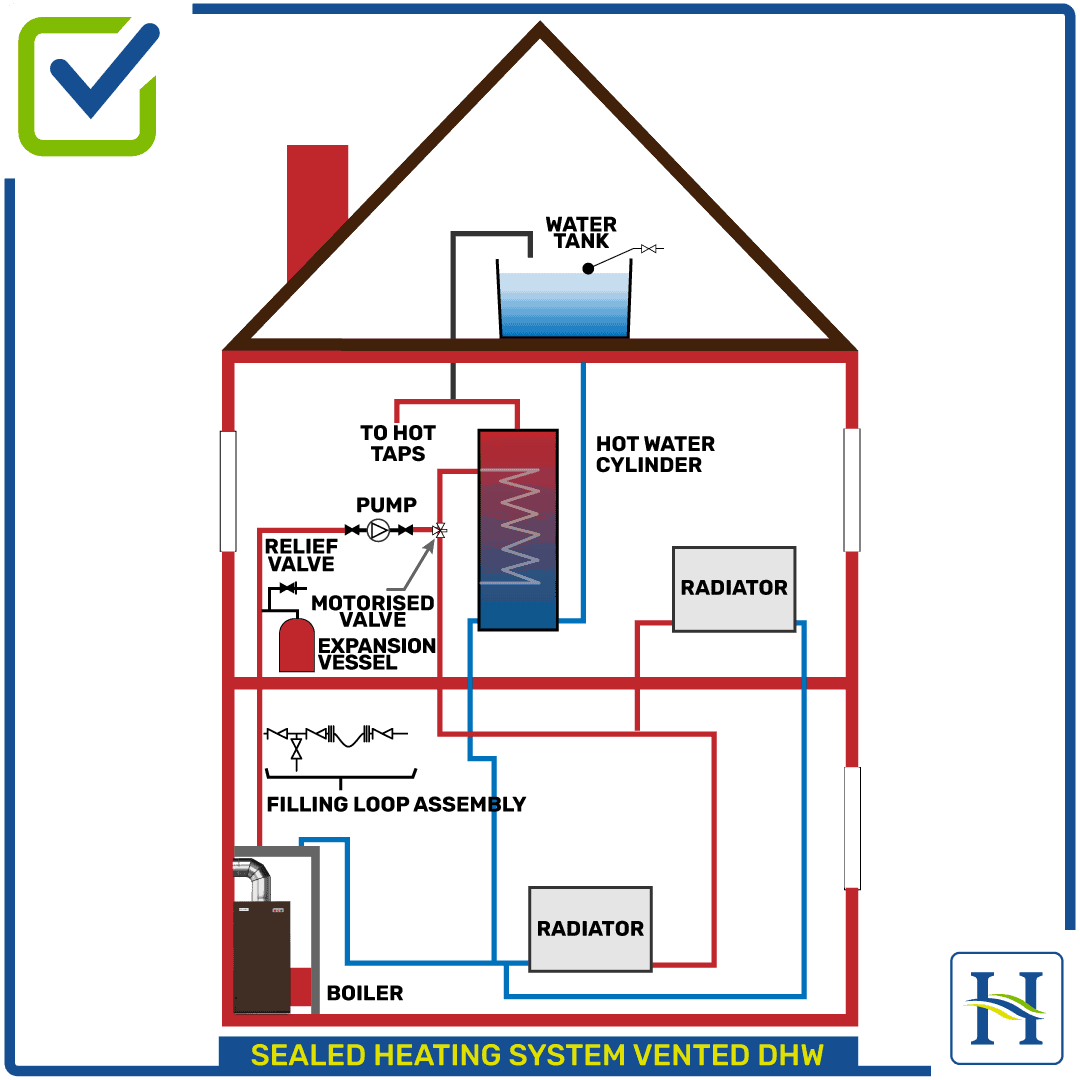

SEALED SYSTEM, VENTED HOT WATER DHW

A sealed heating system incorporates an expansion vessel, this replaces the feed and expansion tank in the loft.

PROS:

- This system is an increasingly popular choice due to the simplified design, and there’s one less tank in the loft to protect from frost.

- A ‘vented’ domestic hot water system can be used where mains water pressure is too low for the installation of a pressurised hot water cylinder.

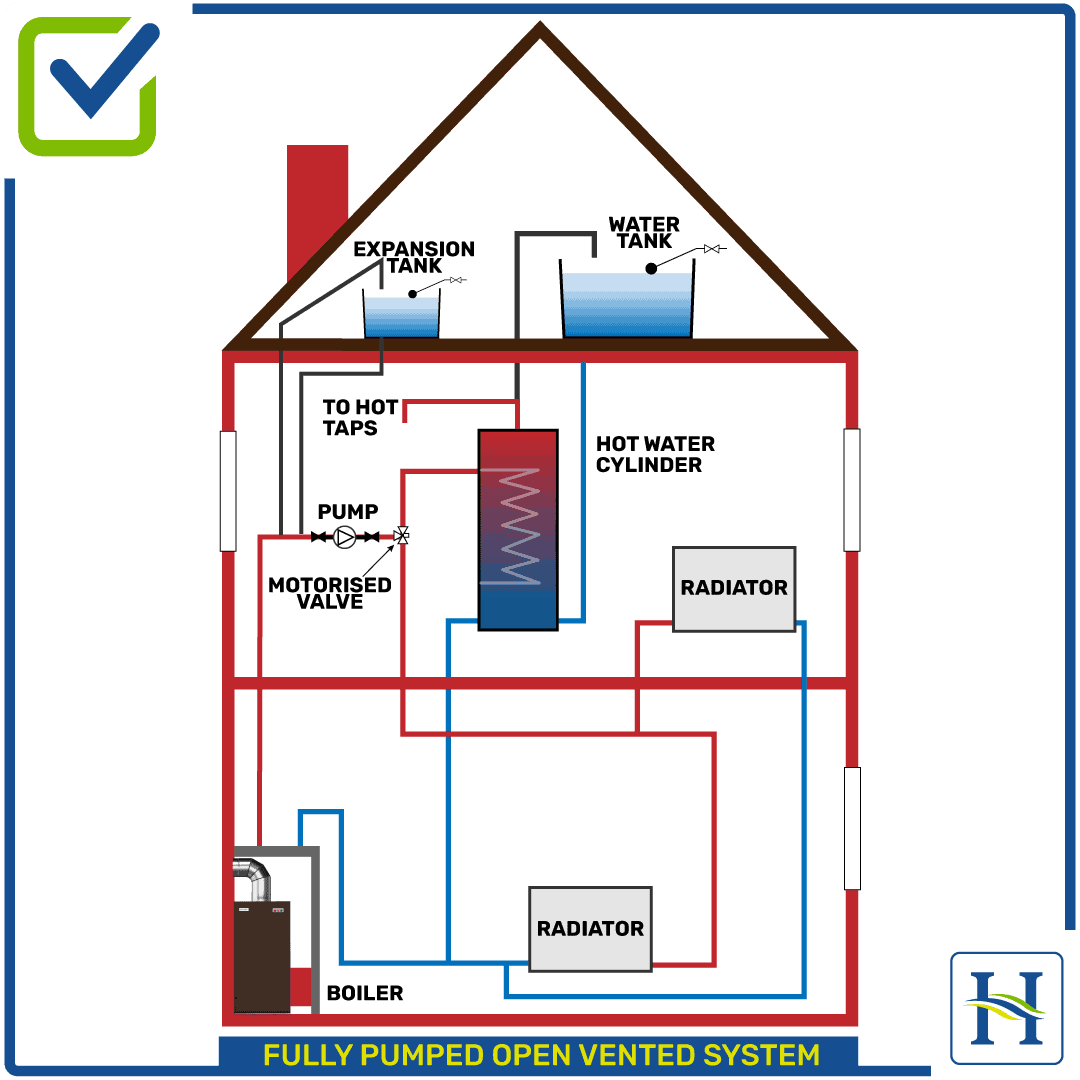

FULLY PUMPED OPEN VENTED

In a fully pumped open vented system, water is ‘pumped’ around the hot water and central heating circuits.

A motorised valve controls the flow of water, either to the ‘hot water’ circuit or the ‘central heating’ circuit. Water tanks in the loft replenish water in the system, with vent pipes above, a safety feature which allows for overflow or expansion of water in the system.

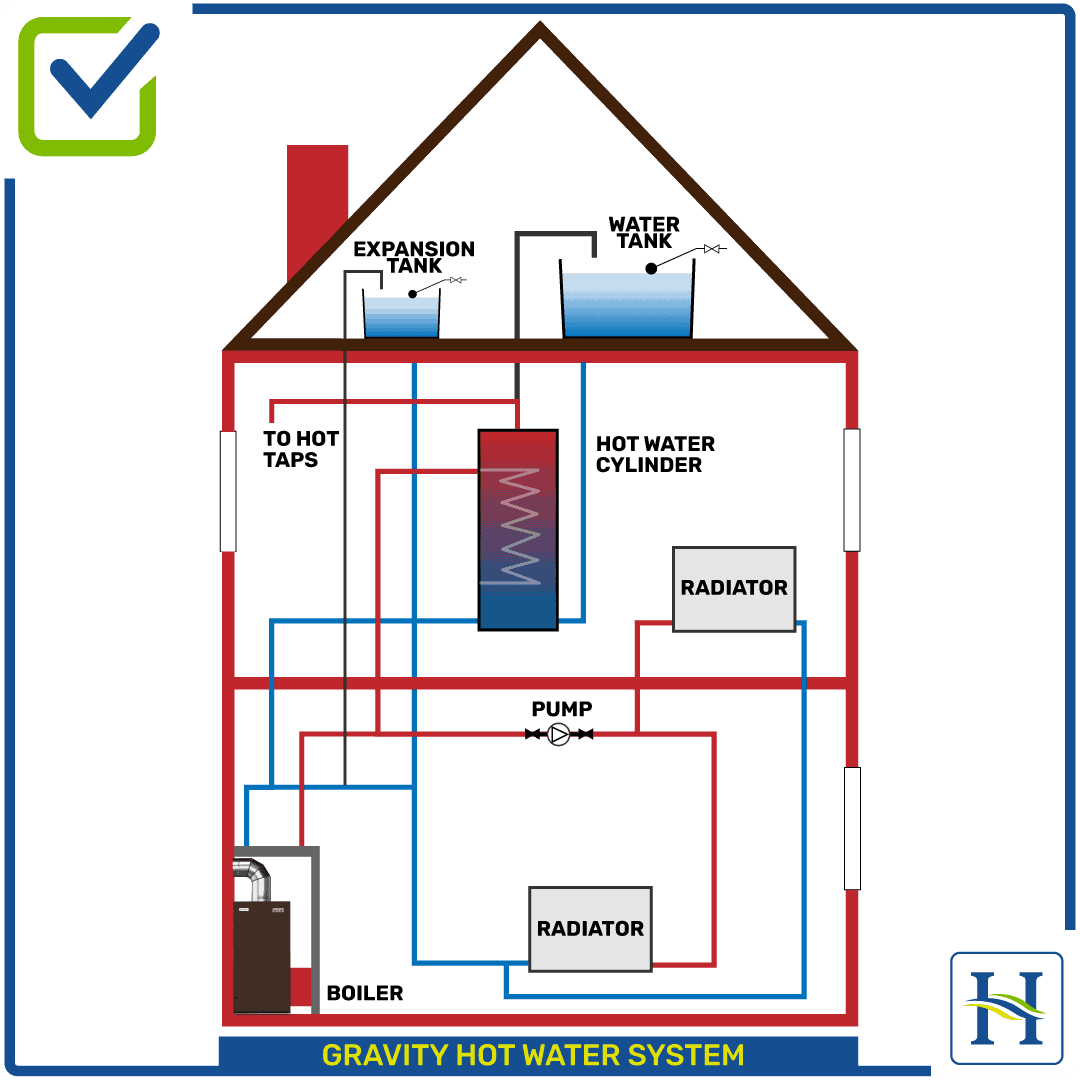

GRAVITY DOMESTIC HOT WATER

In gravity hot water systems, heating of domestic hot water relies on convective action to circulate hot water from the boiler to the cylinder.

A gravity system is easily identified, there will be four pipes connected to the boiler.

CONS:

Although simple it’s not efficient and typically will suffer from the following problems:

- Hot water takes a long time to replenish.

- Water may be too hot.

- Frequent boiler firing, as water thermocycles.

Find out more about the Hounsfield Boilers’ range

Heating Systems More Terms Explained

Condensing Boiler

In a conventional boiler, fuel is burned and the hot gases produced are passed through a heat exchanger where much of their heat is transferred to water, thus raising the water’s temperature. One of the hot gases produced in the combustion process is water vapour (steam), which arises from burning the hydrogen content of the fuel.

Condensing boilers extracts additional heat from the waste gases by condensing this water vapour to liquid water, thus recovering its latent heat. The increase of efficiency can be as much as 10-12%. The effectiveness of this condensing process varies, it depends upon the temperature of the water returning to the boiler, but for the same conditions, it is always at least as efficient as a non-condensing boiler.

It is normal for a condensing boiler to produce a plume of water vapour from the flue terminal; it demonstrates the boiler is working extremely efficiently and may be more prevalent when the boiler starts up. Dependent on the heating system, about 1 litre of condensate per hour is produced. Condensate will have a pH value in the range of 3.5-5, which is about the same acidity as tomato juice.

Non-Condensing Boiler

A non-condensing boiler is similar to condensing boilers except they do not have a stainless steel secondary heat exchanger.

A modern non-condensing boiler running on oil will be around 4% less efficient than an equivalent condensing boiler model.

When installing non-condensing boilers, a Building Regulations exemption is required.

Combi Boilers

Combination boilers, commonly called combi boilers, are similar to conventional boilers with a second heating circuit which instantaneously produces hot water. Often overlooked is the fact that the operating / engineering differences between gas and oil fired combi boilers is significantly different.

Oil fired combi’s, unlike gas, do not have modulating burners to cope with additional heating demand when a hot tap is opened. This problem is addressed in two ways:

- an integral water store making them physically big.

- a larger boiler output than is actually required to satisfy central heating demand; you might end up with a 30kW boiler where a 20kW conventional boiler would suffice and also be more efficient. When the heat store is exhausted, hot water flow of 10-13ltrs / minute @ 35°C rise above mains temperature is around the norm. To fill a bath (112ltrs) will take about ten minutes, provided no other taps are opened.

What are the problems with oil combi’s?

High life-time costs…unlike a gas combi, water is stored in the boiler at circa 80°C, components subjected to this constant residual temperature will fail. Oil fired combi boilers are complex, have bespoke components; they will be more expensive to maintain than a conventional system. Good business for boiler manufacturers, not necessarily the best option for the homeowner!

We do not manufacture oil fired combi or oil fired system boilers, unlike their gas equivalents there are too many technical compromises, not least of which is the high cost of maintenance.

This is why Hounsfield Boilers DO NOT manufacture combi boilers.

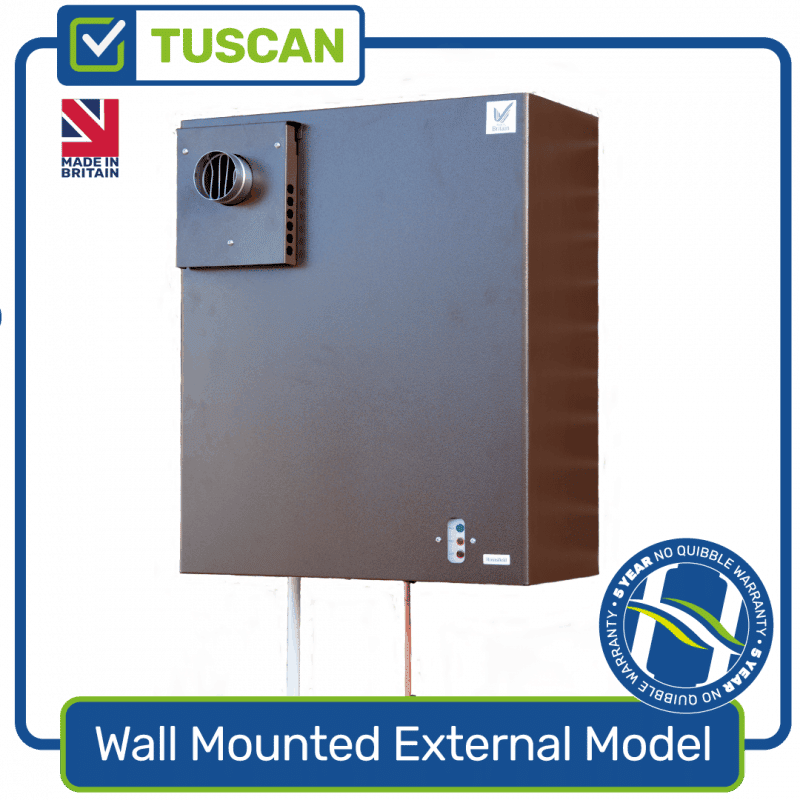

So what’s the solution?

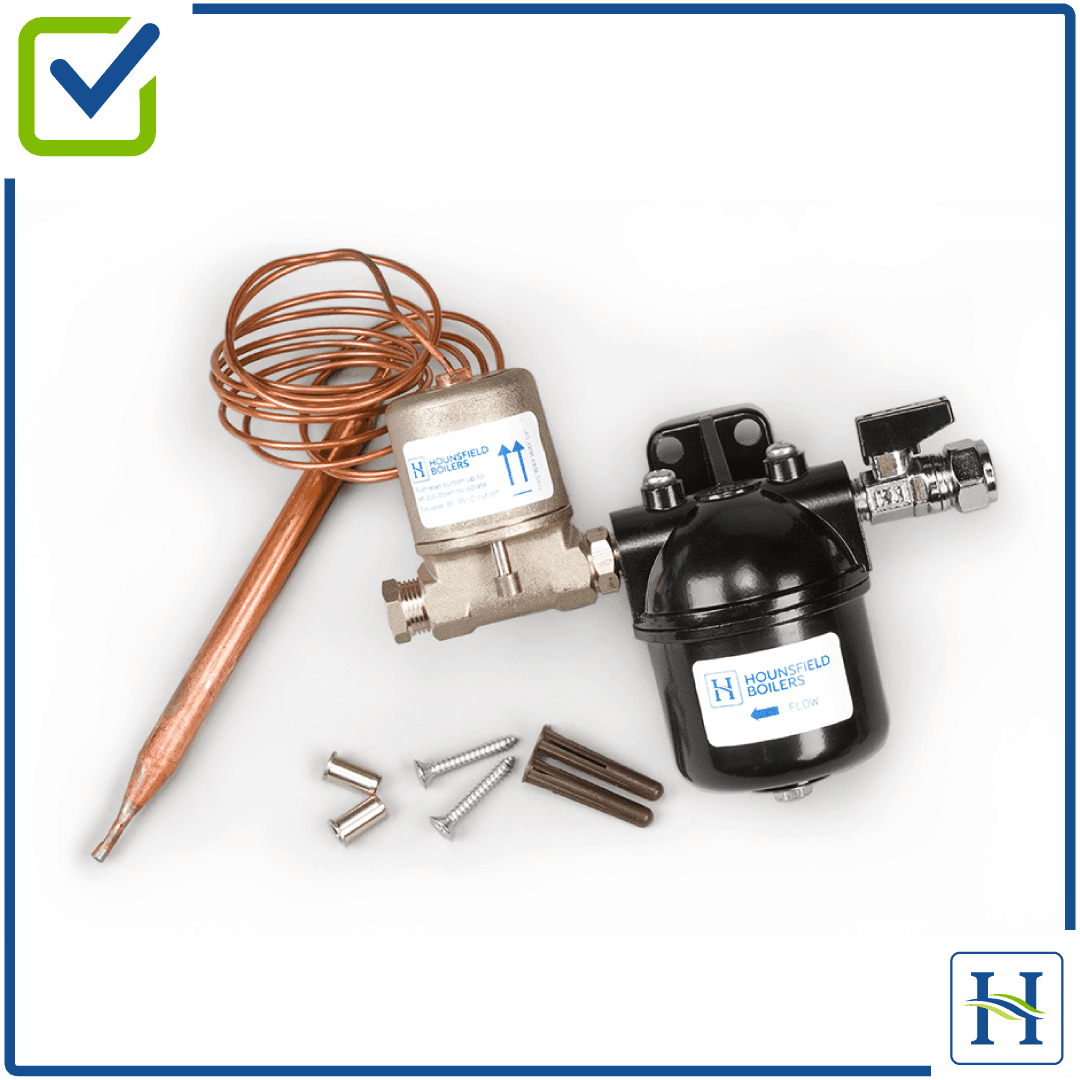

Keep it simple! In so many cases a wall mounted or external heat only boiler with even a small 75ltr pressurised domestic hot water cylinder is a far better option. Such as a Tuscan boiler, with a pressurised domestic hot water cylinder for example a Megaflow, is a far better option.

The benefits: loads of hot water at mains pressure up to 72 litres per minute @ 3 bar vs 10-13 litres for a combi immersion heater for back-up if the boiler breaks down or you run out of fuel industry standard components for low life-time maintenance costs.

Read more Are Oil-fired Combi boilers a compromise

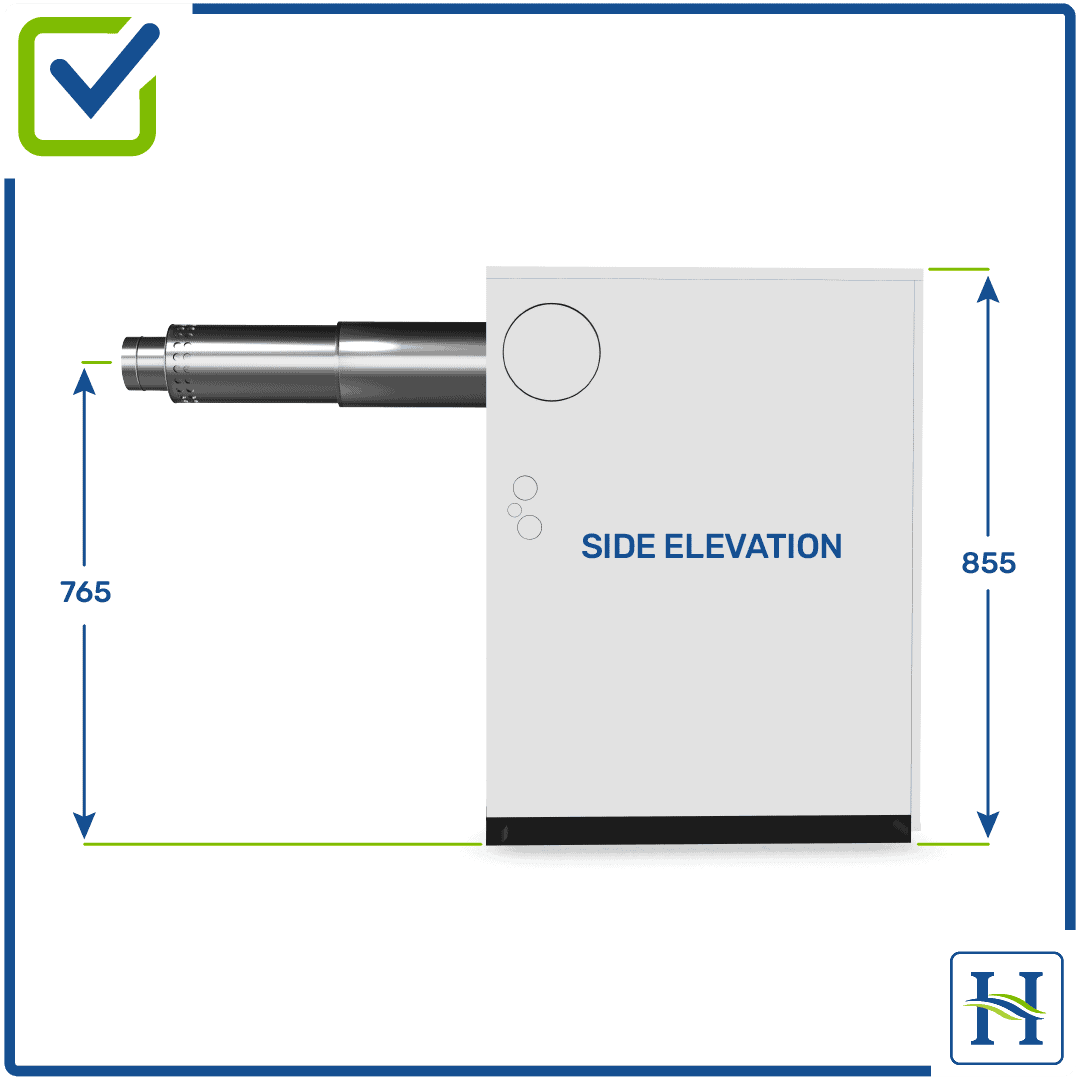

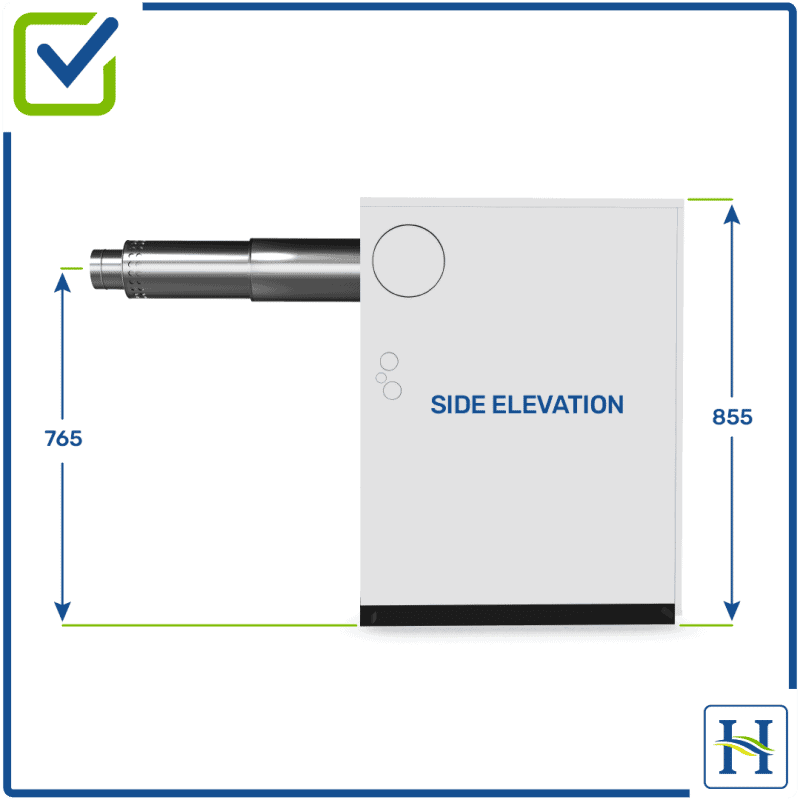

System Boilers

An oil-fired System Boiler includes components such as an expansion vessel (often undersized to fit into the boiler casing rather than suit system water capacity), a pressure relief valve and circulation pump.

They are quick and easy to install. However the residual heat stored in the “mass” of an oil system boiler means that components will degrade sooner than they would if installed remotely making them costly to maintain.

There are better engineering solutions than a system boiler for the end user. At Hounsfield Boilers, we’ve chosen not to manufacture oil fired system boilers.

Why we don’t make system boilers

System boilers are designed to reduce installation time, they contain all the heating system components within the casing, circulating pump, pressure relief valve, and expansion vessel.

However, residual heat in the mass of an “oil fired” boiler will cause components to fail, it’s better to install them remotely. Invariably the capacity of expansion vessel is not big enough, being sized to fit in the boiler casing, rather than the expansion volume of water in the heating system.