OIL-FIRED COMBI BOILERS PERHAPS A BIT TOO MUCH OF A COMPROMISE!

Are they really suitable for ‘modern day’ hot water supply requirements?

Designed in the 1970s with few technical advances since: are they really suitable for ‘modern day’ hot water supply requirements?

It’s essential homeowners are aware of the compromises they will have to make when living with an oil-fired combi boiler. Often overlooked are the significant technical/ engineering differences between gas and oil-fired combi boilers.

Consider

1. Modulating burner

– Gas fired combis have modulating burners: when a hot tap is opened, a gas valve opens (modulates), passing more fuel into the burner / boiler to satisfy heating demand.

– Oil fired combis have fixed rate burners: they cope with additional heating demand in two ways:

a. An integral ‘heat store’ makes them physically big – often twice the size of a conventional heat-only boiler.

b. A larger boiler input (kWatts) than is actually required to satisfy central heating demand: typically a 30kW boiler where a 20kW heat-only boiler would suffice. It’s like running a Jaguar V12 when a Nissan Micra would do the job and be far more efficient!

2. Hot water ‘temperature rise’ and ‘water flow rates’

– Temperature rise and flow rates quoted by manufacturers must be treated with caution. Flow rates of 10 – 13ltrs per minute @ 35°C degree temperature rise above mains water temperature is around the norm in practice.

– Temperature rise will fall after the integral ‘heat-store’ in the boiler is exhausted.

– Temperature rise will be lower during winter months when the ‘mains in’ water temperature drops below the norm of say 10°C degrees.

– To fill a bath, 25 gals / 112ltrs will take about 10 minutes, providing no other taps are opened.

– Showers, again temperature and flow rates will change when other taps in the system are opened.

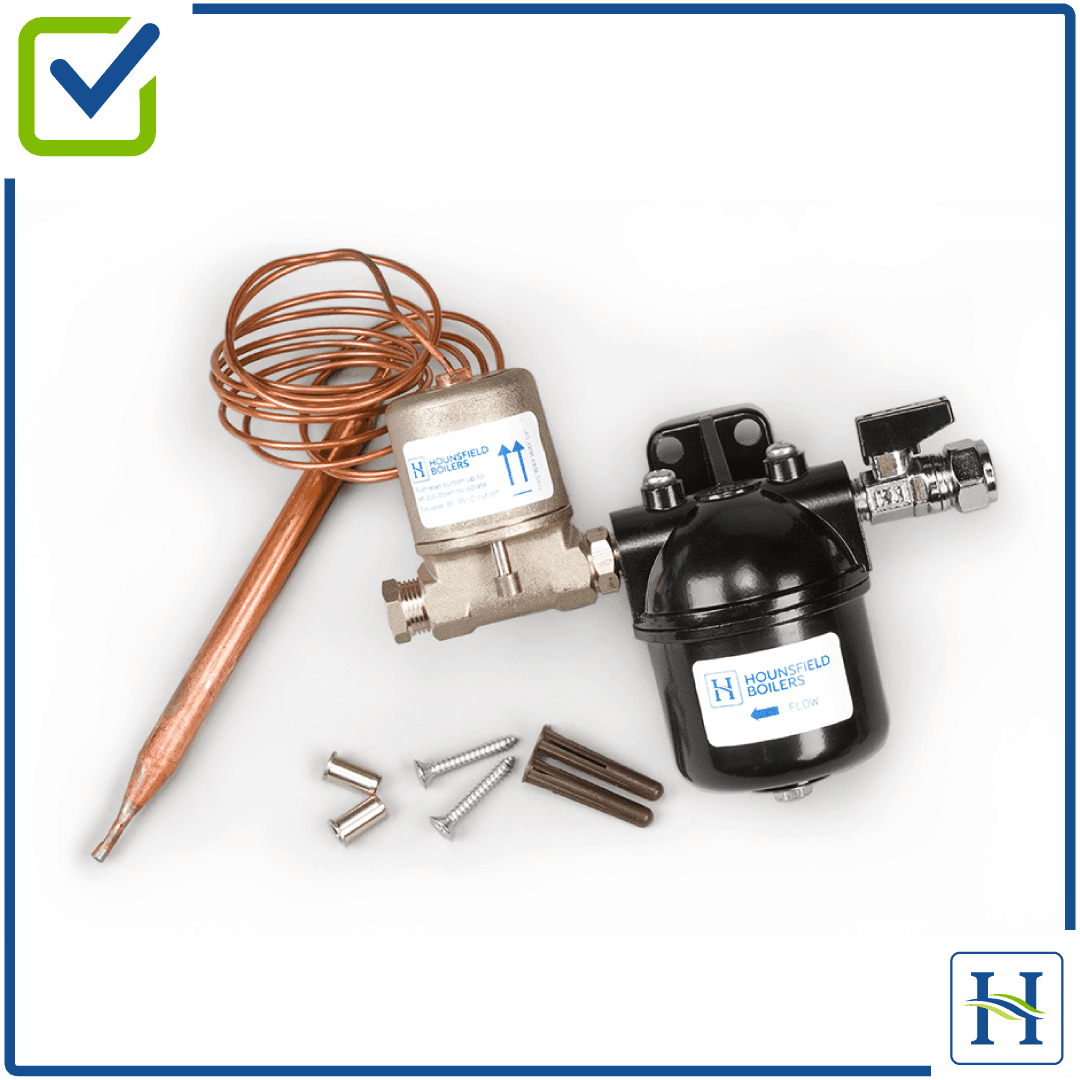

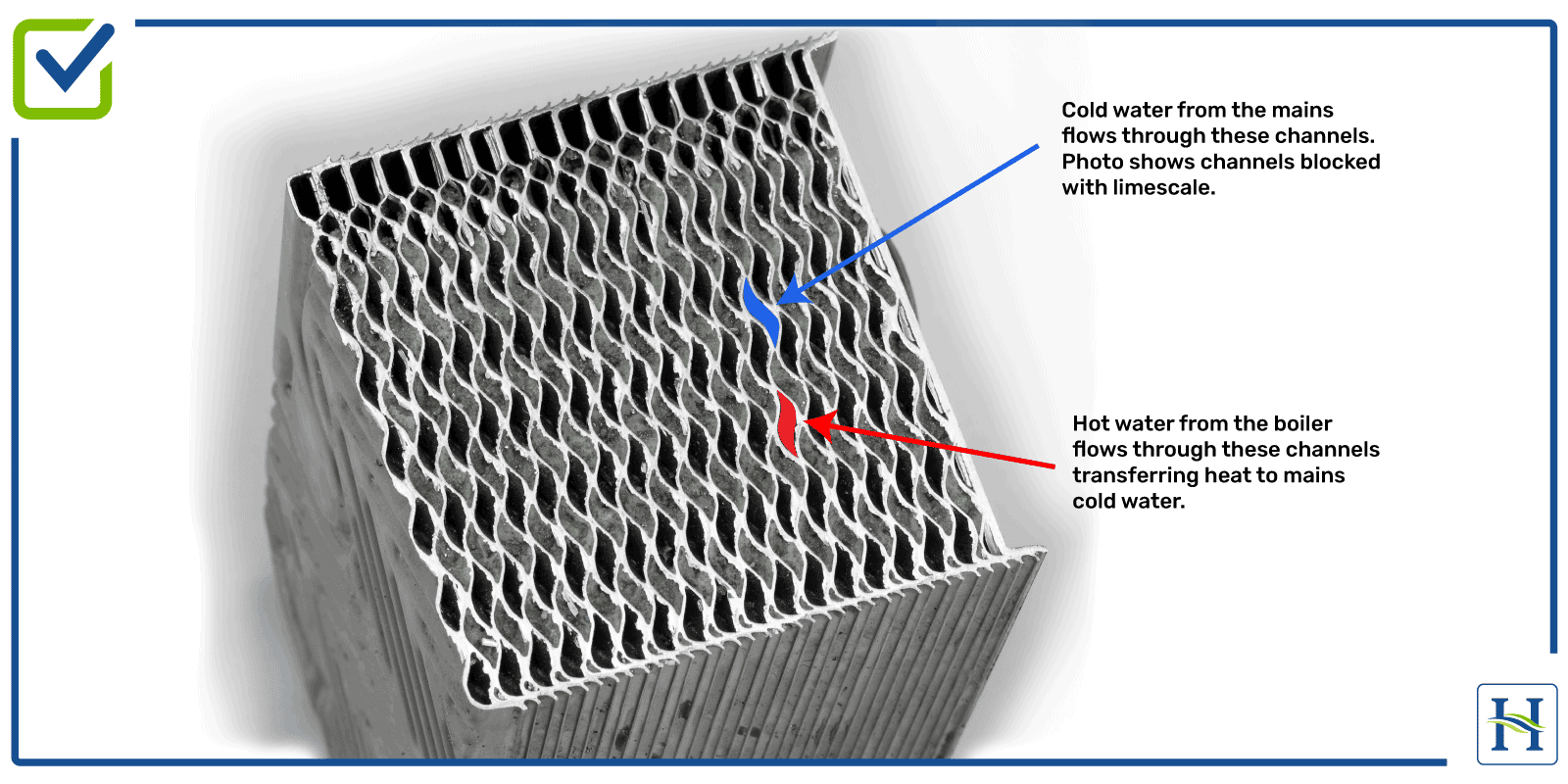

3. Hard water problems

– Hot water is produced via a small plate heat exchanger. These get scaled-up just like a kettle and often need replacing.

– A mechanical water softener is essential. They take up space. Magnetic / electric in-line scale reducers are available but there is no scientific evidence to prove they work.

Photo of a plate heat exchanger, cross-sectioned, to show alternate layers for cold to hot water transfer.

At just 80 x 80 x 180 cm (3″ x 3″ x 7″ inches) a combi boiler relies on this component to produce all hot water requirements.

4. Hot water back-up

– If the boiler fails, for example if you run out of fuel, there’s no back up for hot water, as there would be with a conventional hot water cylinder with an immersion heater, this alone can lead to expensive emergency engineer call-outs.

5. Life time costs

– Combi boilers are complex and have bespoke components: they are more expensive to maintain than a conventional system which uses industry standard components.

So what’s the answer?

Keep it simple! A heat-only boiler with even a small 60ltr pressurised hot water cylinder will provide nearly twice the hot water storage of a combi boiler.

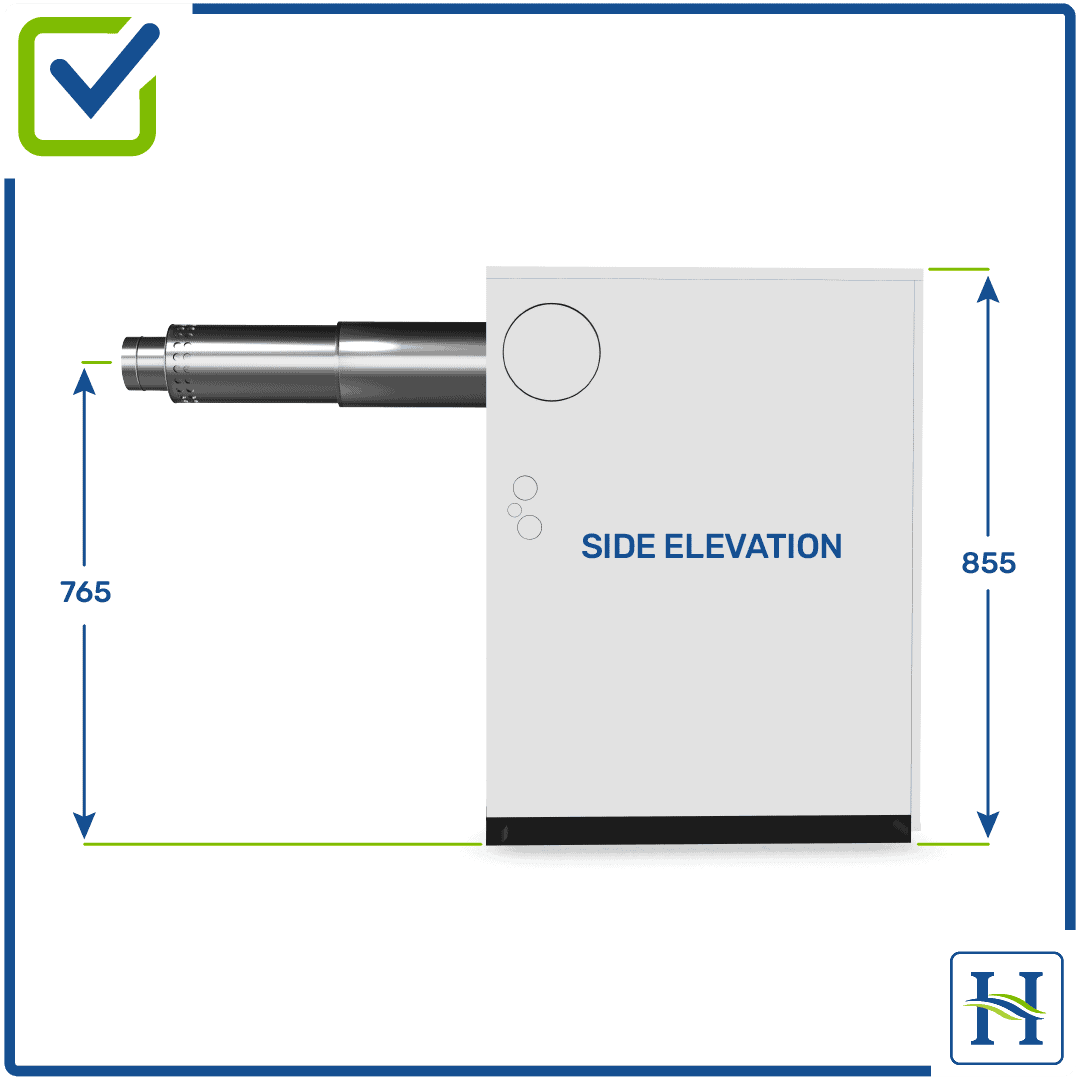

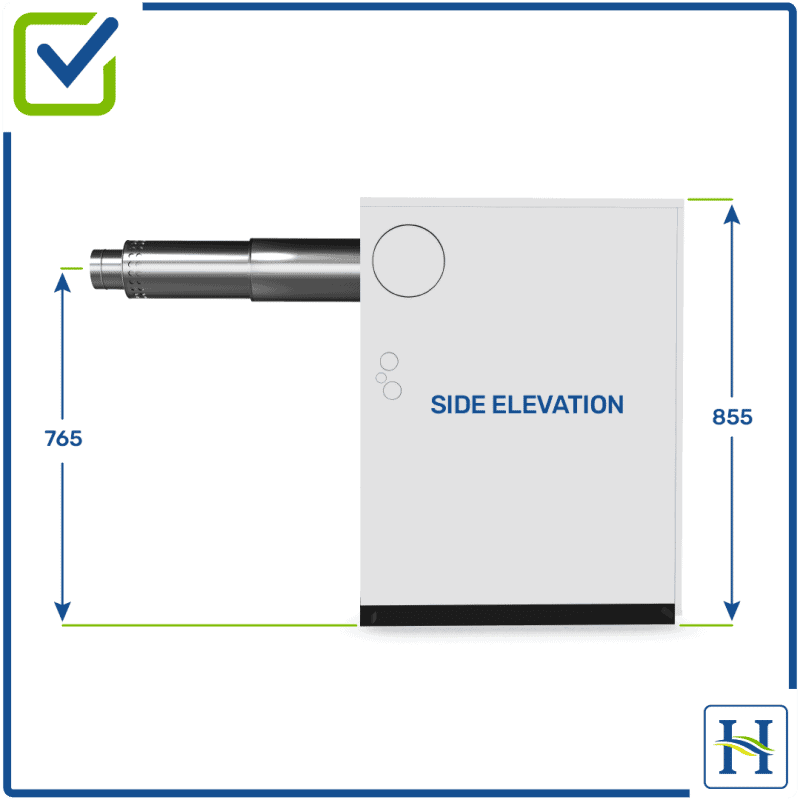

There’s no need for an airing cupboard and at just 475mm x 600mm a 60 litre cylinder would work along side our Kitchen, External or Wall Mounted Boiler Models: a similar foot print to a combi boiler, a far better solution!

Pressurised cylinders such as the Megaflow or Stelflow will provide many years maintenance free service.

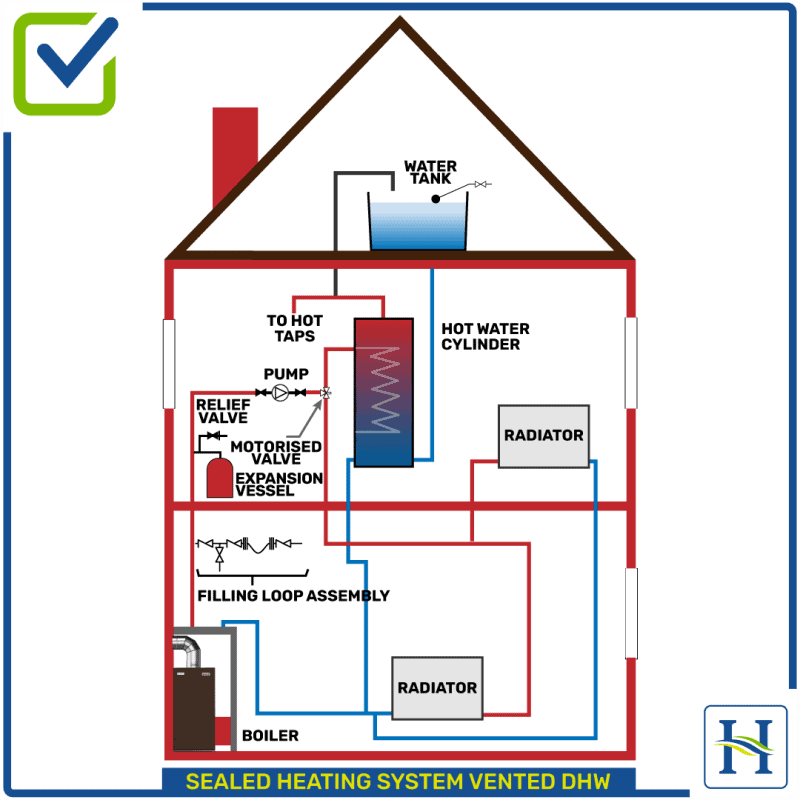

For more information see Sealed Heating System unvented in Heating Systems Explained. Download the pdf ‘Are oil-fired combi boilers a compromise‘.

But if you’d like to learn about gas-combi boilers and how they work, check out this blog.

Find out more about the Hounsfield Boilers’ range