We never talk about the throw away culture that dominates the heating and plumbing world

In what seems to have become a ‘disposable heating world’, Andrew Hounsfield, owner and inventor of the Hounsfield Boiler, says his company is making waves to create products built to last.

I had worked in the domestic heating industry for many years, and I didn’t like the way the industry was moving. Price instead of quality had become the major driver and it saddened me that increasingly inferior products were making their way into the supply chain. At this stage, I decided it was time to move on and design my own boiler.

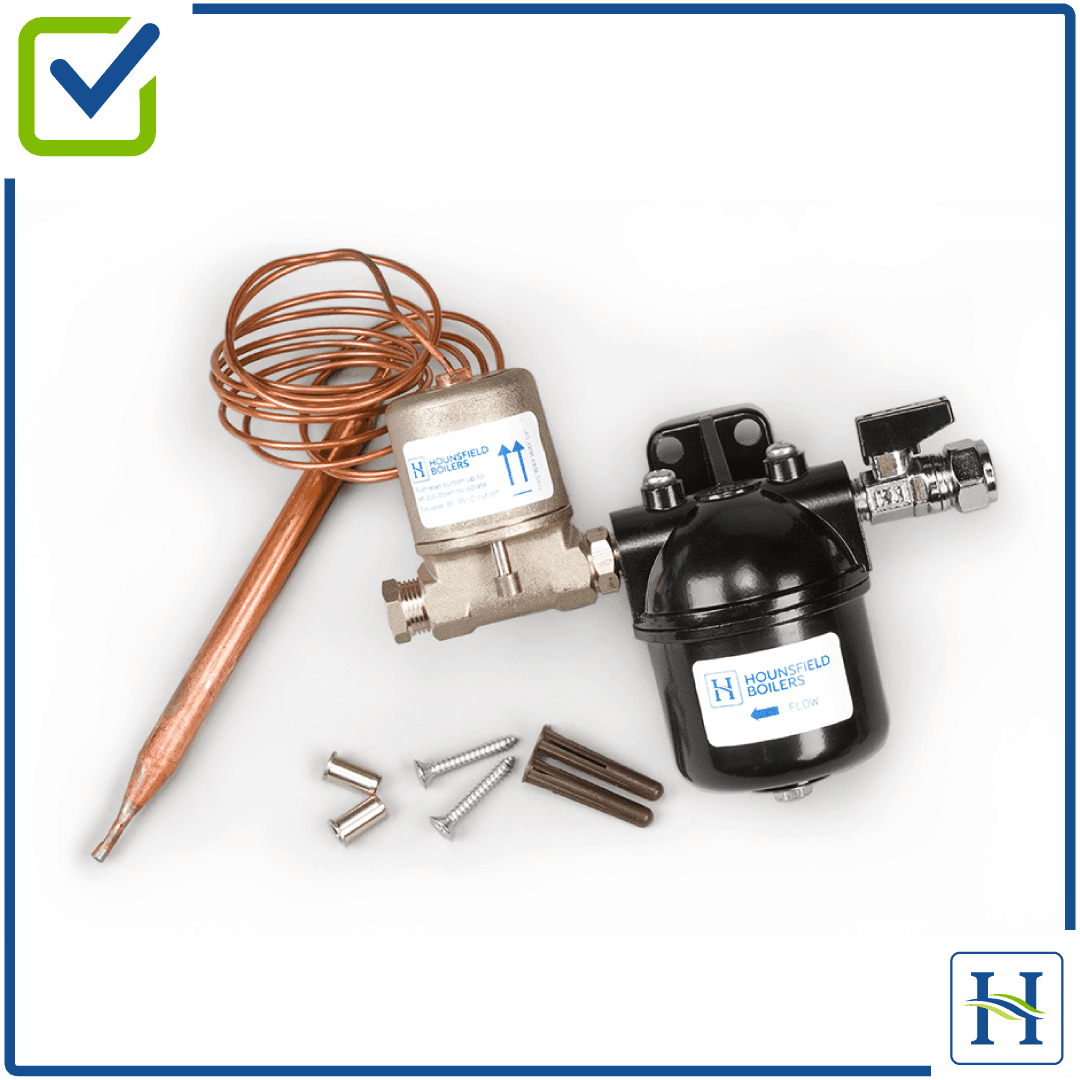

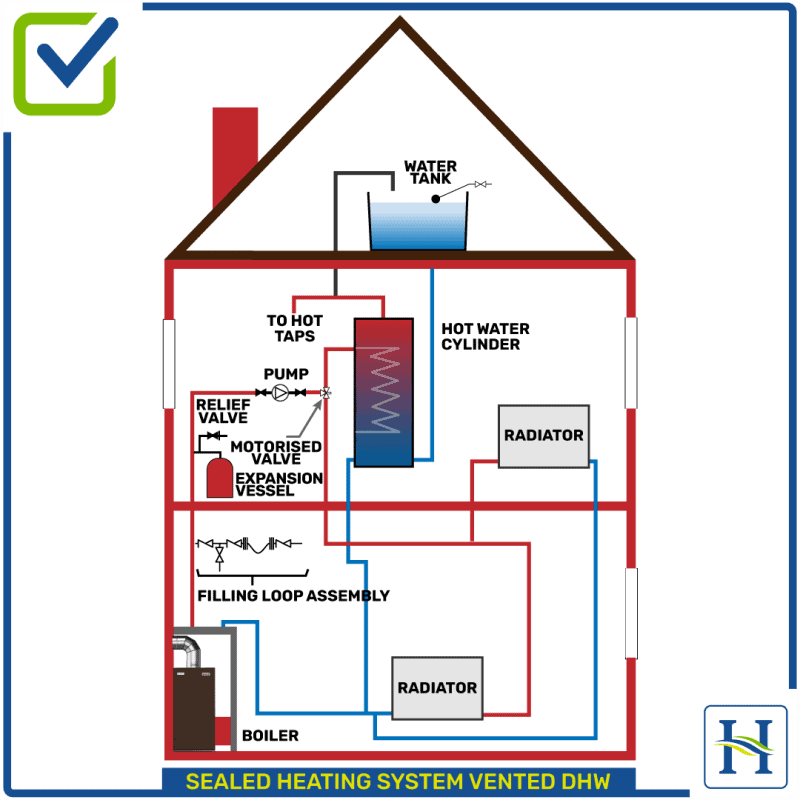

I wanted the Hounsfield Boiler to benefit from a wide variety of stand-out qualities, such as long-life components, to ensure the boiler would stand the test of time. Industry has become very ‘throw-away’ with the use of mediocre components accepted as the norm; perhaps the objective being to generate more business from spare part sales? Call me cynical, but how do we differ? A good example of our high grade parts is the specification of the hose we use for flexible oil lines, which has a Teflon core and stainless-steel braiding, it is aircraft grade material, instead of the industry standard – rubber or thermoplastic – which we all know will degrade and require regular replacement. Oil leaks caused by failed out-of-date hoses can result in expensive insurance claims for homeowners or engineers, a situation which wouldn’t occur if manufacturers supplied hoses which were “fit for purpose”.

For homeowners and heating engineers, “warranty,” in recent years, has become a top-of-mind big issue, no doubt a result of bitter experience! However, warranties still contain reams of small print, perhaps designed as a “get out” clause by most manufacturers, or an income stream for spare parts/replacement boilers? Manufacturers are also demanding that certain components, such as supposedly ‘long life’ hoses, which only last a few years, and even fuel pumps are included in a list of items that need to be replaced as a condition of warranty – it really does beg the question, what is the lifespan and what does warranty actually mean?

As an industry we all talk about becoming increasingly environmentally friendly; that’s great. I applaud any player within the industry which ensures their products run more and more efficiently. However, we never talk about the throw away culture that dominates the heating and plumbing world. How can it be good for the environment, if we’re constantly manufacturing and throwing away components or boilers because they were simply not made to last? Yes, some of our materials can be recycled, but the majority are thrown on landfill, which has a devastating effect on our environment.

Our ethos is different; we design with homeowners and installers in mind. Our products are built to last and do exactly what they say they will do. I strongly believe we should go way beyond offering one, two, or even five-year warranties. What is the point of increasing efficiency if the boiler itself is only built to last five or ten years? How is this reducing our carbon footprint? If we produce boilers that we expect to last 15 or 20 years minimum, then the raw materials to manufacture will be greatly reduced.

The industry has achieved this in the past, Last year I replaced a 50-year old model, on average older boilers are lasting 20-25 years, a period when warranties would have been just 12 months, we really need to start a sea of change.

I’m not naïve, I do realise that some components will experience wear and tear and will need to be replaced. Boilers need to be designed to allow heating engineers easy access to all areas of the boiler for maintenance work and replacement of vital components. How many times have you heard an engineer turn to a customer and say: “I can fix it, and the part is small, but I would have to take the boiler to pieces, which will take me all day, so it would be cheaper for you to buy a new boiler,” this is unacceptable.

Our boilers are made to last and come with a no quibble five-year guarantee. How do we make them so robust? We search and test for the very best components and although they may make the boiler slightly more expensive to buy, the return on investment for the homeowner is undeniable.

At Hounsfield our focus is on lifetime performance, energy-efficiency and ease of installation and maintenance for heating engineers. It would appear that many of the big brands in the industry are more interested in profit and blinding customers with false warranties. To a degree I don’t blame the big brands, but I really do question why Government or OFTEC, aren’t forcing the industry to take the same steps we have in developing more durable boilers.

The Hounsfield Boiler has been shortlisted for H &V News Best Domestic HVAC Product of the Year: Heaters and Boilers. To discover more, visit www.hounsfieldboilers.co.uk.

Find out more about the Hounsfield Boilers’ range